The Basic Principles Of Fire Rated Glass Panels

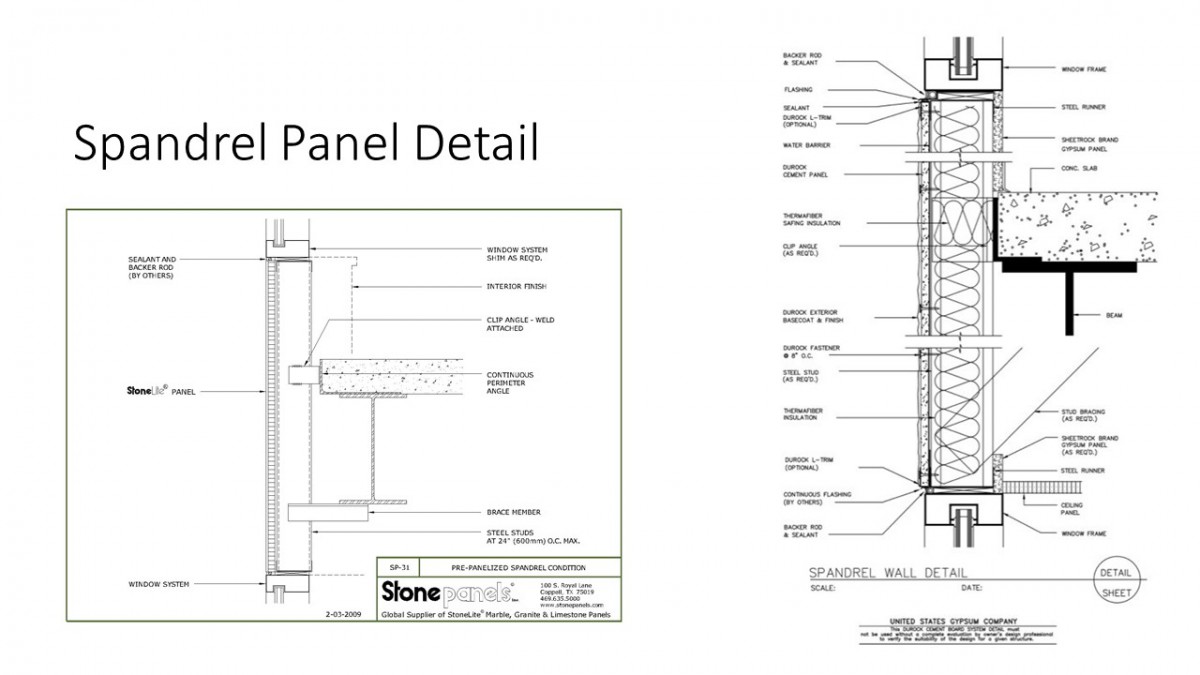

Usage thermally broken or thermally improved aluminum structures for best performance. At the perimeter of the curtain wall, the thermal break has to be appropriately placed relative to the wall system/insulation to avoid revealing the light weight aluminum framework inboard of the thermal break to cold air ("brief circuiting" the thermal break) (double glazed glass panel).

Sometimes, there are problems connecting to having excessive uncontrolled daytime, sometimes referred to as glow. The difficulty is to strive for the greatest visible light transmittance (VT) and the least expensive solar warm gain coefficient (SHGC) while not stopping the glass from being as well reflective when checked out from both the outside and also the inside, while controlling glow (double glazing panel replacement).

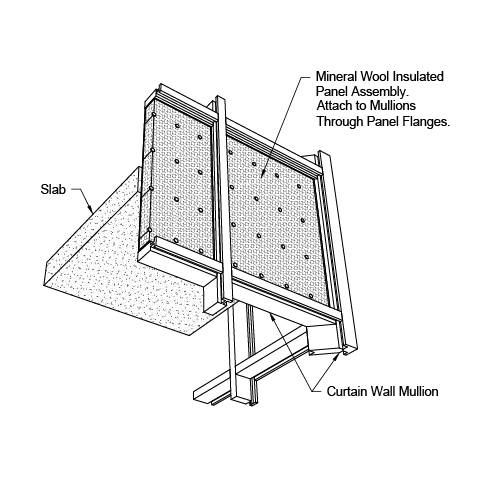

NFRC 200 is used to figure out the VT and also SHGC values while the solar optical homes are identified using NFRC 300. Typically, for items a lot more commonly readily available on the marketplace, the previously mentioned worths are conveniently offered from glass manufacturers/fabricators. Light weight aluminum: Class I anodic finishings (AAMA 611, supersedes AAMA 606, 607 and also 608) and also high efficiency manufacturing facility applied fluoropolymer thermoset coverings (AAMA 2605) have excellent resistance to ecological degradation. The units ought to be entirely assembled in a manufacturing facility and also shipped to the website for setup on the structure. The systems are placed on the floorings, packed in crates, using the tower crane and also decreased into place making use of a smaller sized crane or hoist had by the glazing contractor. The mullion dimensions tend to be somewhat larger than a stick system because of their open area as compared to television form of a typical stick curtain wall surface section.

Our Double Glazing Panel Replacement Ideas

Systems can be put together in a factory while the architectural frame of the building is being constructed. Where stick systems require multiple steps to erect as well as seal the wall surface, unitized walls show up on the website completely constructed allowing the floors to be enclosed extra swiftly. Unitized systems also require less room on website for format hence supplying an advantage for urban sites with room limitations.

The interlocking upright mullions will normally have 2 interlocking legs. One leg will be in the airplane just behind the glazing pocket and the other at the interior face of the mullions. The interlocking leg in the plane of the glazing pocket will certainly be secured by gaskets as well as is the main line of defense against water as well as air infiltration.

Equipments whose linking legs lock additionally compromise the ability of the system to suit activity. Some unitized designs are delicate to little irregularities in the spacing of nearby modules; for instance, if the component joints are slightly out of resistance, gaskets read what he said might not be properly compressed as well as dampness protection might experience.

These upstanding legs have gaskets that secure against the wall surfaces of the lower straight. Some styles supply one upstanding leg that gives one line of protection versus air as well as water infiltration. Extra durable systems will provide two upstanding legs with gaskets on both legs. A splice plate or silicone blinking that is mounted at the top of both nearby units as they are set up on the building is commonly called for.

How Double Pane Glass Panels can Save You Time, Stress, and Money.

The stack joint is the straight joint where units from adjacent floorings meet. Positioning the pile joint at the sill of andersen windows glazing panel the vision glass (usually 30" above the floor) will certainly reduce the measurement of the vertical mullions. This positioning utilizes the back period of the mullion above the anchoring factor at the piece to counteract the deflection of the mullion below the piece.

While two tale spans are viable, the weight of the unit is doubled which may call for boosted architectural capacity to suit the raised load. Wind load bracing must be incorporated at the single span height to stay clear of raising the upright mullion dimension to suit the raised span. Steel can be contributed to a unitized system to increase its extending ability.

Big devices may also enhance transportation expenses from the manufacturing facility to the website and also erection expenses of putting the units on the structure. Thermally damaged unitized systems are readily available, making use of comparable innovation as that utilized in stick drape wall systems. The solution life of also one of the most durable drape wall surface might be shorter than that of long lasting adjacent wall surface claddings such as stone or brick masonry.

The life span span of parts Continue that are mated with the curtain wall right into an assembly ought to match the service life span of the drape wall itself. Call for resilient flashing products, non-corroding attachment equipment and also bolts, and also moisture immune products in regions subject to wetting. Lab screening: For jobs with a significant amount of custom-made curtain wall, require lab screening of a mock-up curtain wall surface prior to finalizing job store illustrations.